This page is a summary of a few things I made over

the years, in roughly chronological order.

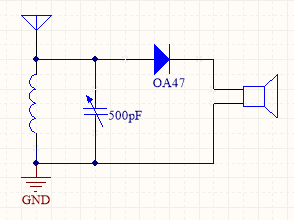

Crystal Set

Back in the 1950's, most kids started out building a basic crystal set.

I was fortunate in that my parents' house had a large antenna & a good earth, put in

when the house was built in the 1920's, & radios were far less effective than they

later became. I paid for the parts for the set, & my father matched me by providing a pair

of proper high-impedance earphones. I had ordered the parts from my local radio shop, & was

quite disappointed when they supplied a ready-wound tuning coil, rather than the spool of

wire I had expected (I intended to wind the coil myself.) Nevertheless, it worked very well.

It was built in an old wooden cigar box.

If you want to try this yourself, 2 tips:

- Use a germanium diode if possible: it is far better than silicon for this. If you have

to use silicon, it may be worth trying a Schottky type.

- The earphones must be a high-impedance type (mine were 4kΩ). Low-impedance types,

as used for computers, personal music players etc., just will not do. You may be able to

use a small audio step-down transformer, I haven't tried it myself.

|

|

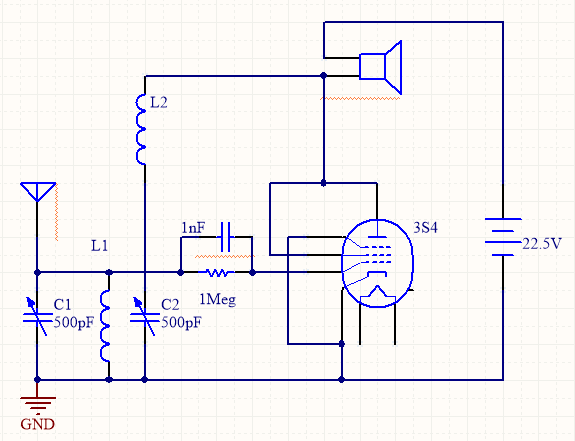

D5B Receiver

This was a logical progression from the crystal set. The parts were bought as a kit;

I simply had to assemble it. I have used an available pentode symbol: the 3S4 tube is

directly heated, so there is no separate heater. The schematic is from memory, &

very much E&OE.

The learned will at once recognize the (in)famous super-regenerative

design. A station is tuned in using L1/C1, then a degree of positive feedback is applied by

adjusting C2 (coils L1 & L2 are magnetically coupled.) The danger with this circuit is

that the most sensitive spot has it just on the edge of outright oscillation: it readily

radiates broadband interference. Back then, people didn't worry so much about this, but

today it would be asking for trouble. If you want to experiment with a super-regen, put a

separate RF amplifier between it & the antenna.

As with the crystal set, a high-impedance earphone is required.

|

|

Tape Recorder

This design was published in the UK magazine Practical Wireless,

February 1961 & following. My build followed the magazine quite closely, the major difference being

the use of a Collaro Studio tape-deck, rather than the Motek which was specified. However it worked

very well. This project taught me the importance of careful layout with high-gain tube amplifiers:

they can readily pick up from their own outputs, & burst into oscillation.

Simplex-III

The 8-bit computer I built back in

1976; it has its own page.

P112

A Z-80 powered CP/M board, sized to fit on a 3-inch disk drive.

It also has its own page. Although I no longer sell this, it still has

a following.

Igor-II

This is a vacuum-tube audio

amplifier, built around 2007. An OTL

design using ex-Soviet 6C33 output tubes directly connected to the

speakers, it delivers 25+25W continuous power.

Why was it named Igor? The first breadboard version

used a collection of miscellaneous transformers to generate the

numerous voltage rails, & looked like something from a 1930's

Frankenstein movie. “See Igor, Russian tubes! Now ve shall ze

vorld astound!” (Sorry🙂)

The first version was purely

experimental, & went through several changes in topology. Version

2 settled on a conventional totem-pole output stage, with a

deliberately asymmetrical phase-splitter to compensate for the

different gains in the upper & lower limbs of the totem-pole output

stage.

This

sequence shows how it was built. The mechanical design began with

a 3D model using Solid Edge, from which the sheetmetal drawings were

taken off. The parts were professionally

fabricated, & the external parts powder coated.

The schematic of one

channel is shown. The accompanying “PCB layout” is a

dummy, which was drawn up to assist in planning the component layout

in the chassis.

V1 implements a cascode first stage, which provides

most of the gain.

The phase-splitter, V2, has a very small cathode

resistor (R7), this causes the stage to run unbalanced, with more

gain in V2A than V2B. This compensates for the extra gain provided by

V5, the lower limb of the output block. The upper limb, V4, is a

cathode follower, & so contributes no voltage gain. The cathode

supply (via R9) is switched in the control module, enabling the

controller to provide a “soft-start” function, to avoid

thumps on turn-on.

The cathode follower V3 provides the ability to drive

the output tubes into grid current, so greatly increasing the

available output. R3 & R17 provide some 12dB of negative

feedback.

The power supplies are shown here.

The HT & LT transformers were custom built. Each is controlled by

a solid-state relay, which switches instantly, not on zero-voltage.

The control module uses this ability to soft-start the supplies,

gradually increasing the duty cycle. A slow start is provided for the

tube heaters, & a rather faster one for the HT rails. The edge

connector at centre-right is the control

module.

Control is implemented by software

in an Atmel AtMega-8 microcontroller.

Door Control

A basic remote-controlled garage

door opener. Yes, these are quite inexpensive to buy, but I took

it as a challenge to build one (both the electronic and mechanical

parts) using stuff in my junk box.

The motor came from an ancient

“washing machine” disk drive, feeding a 30:1 worm drive

from the junk box. This is followed by an intermediate shaft (top in

the picture), with a dog-clutch

operated by the large black knob, providing for manual operation.

A commercial 433MHz

receiver feeds the control PCB. The

software is available.

The motor has 2 identical windings

spaced 90°

apart. To start the motor, one winding is powered directly, & the

other received power phase-shifted by a series capacitor. Once

started, the phase-shifted current is stopped, & the motor runs

on one winding. Interchanging the 2 windings runs the motor in

reverse.

The

door motion is sensed by industrial reed switches at the top &

bottom of the track.

Digital Clock

Another simple project, the point

of this one was to include backup via a supercap,

to enable it to survive the too-frequent power outages in the Perth

Hills. 3 copies were built, & used

around the house.

The specification

provides a basic functionality, using 3 rear-mounted buttons. The

software is available.

Soldering Oven

A cheap benchtop oven is

re-purposed to solder SMT circuit boards. Two soldering profiles are

stored in EEPROM, & can be changed by reloading the software.

The original controls were removed, & replaced by

a custom design. A panel was made from the

fireproof material used for electrical switchboxes, & fitted to

the side of the oven chamber. Control components are fitted to this

panel.

Temperature is sensed by a K-type thermocouple,

visible at the right, just under the transformer. The control

PCB uses the same Atmel CPU as my previous projects. The software

is available. Inputs are the thermocouple & panel switches. There

are 3 isolated triac outputs: the 2 heating elements & a fan,

salvaged from an old microwave oven.

Several fine-pitch SMD boards have been successfully

soldered in this oven.

TRIDOX

A 3-dimensional noughts-and-crosses program.